PRODUCTION

Machinery manufacturing is an activity that involves the manufacture and assembly of machine parts or components through a manufacturing process. In this process, a production process is carried out, starting from the design of a machine, and ending with material selection, processing, assembly and testing.

Machine manufacturing usually includes the following steps:

Design: Designing a machine or machine part in accordance with needs. At this stage, engineers determine the geometry and properties of machine parts using CAD (Computer Aided Design) software.

Material Selection: Selection of suitable materials for the designed machine parts. Material selection is based on durability, strength, thermal properties and other requirements.

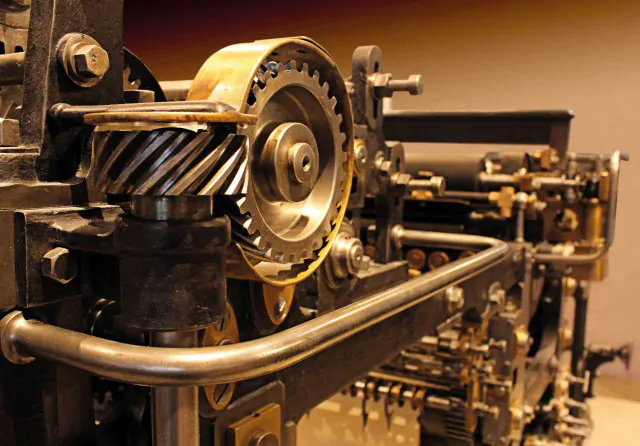

Assembly: The creation of the machine or machine components by assembling the machine parts produced. During the assembly phase, it may be necessary to assemble parts correctly and add other components such as fasteners, bearings, gears, actuators.

Testing and Quality Control: Checking the conformity of the manufactured machine or machine components to functional and quality standards. At this stage, the performance, durability, accuracy and other features of the machine are tested. Quality control procedures vary according to specifications and customer demands.

It is an important process used in many sectors such as machinery manufacturing, automotive, aviation, energy, food processing, textile, medical devices. This process enables the production of complex machines that require high precision, reliability and efficiency. In addition, the use of advanced technology and automation plays an important role in machine manufacturing.